-

A research team led by Lee Hwang, Professor of Architecture at Ajou University, developed a building façade module that automatically responds to changes in temperature similarly to the way a cactus does—by opening and shutting “stomata” to adjust its own temperature.Prof. Lee’s research team used smart materials and 4D printing to develop a temperature-sensitive building façade (visor) module. Related research findings were announced in the international Journal of Building Engineering on August 8, 2021. 4D printing is a technology that adds a time dimension to 3D printing, which prints three-dimensional shapes, thereby printing materials that change according to time.The research team used shape memory materials that change shape according to temperature to imitate how cacti open and close their stomata. Cacti breathe through their stomata and use them to control light and humidity, thereby helping them survive in the desert. The research team combined shape memory nickel titanium alloy with shape memory high polymer, which allows the shape memory alloy to contract as the temperature rises and close its visor to shut the sunlight out. As the temperature drops, the shape memory high polymer curves outwards to open the visor.With a miniaturized architectural structure, the research team verified that shape memory composite materials can be used to automatically open and shut an exterior wall according to temperature. Previous studies attempted to use “smart” materials that changed shape with the temperature, but their restoring force, which is the ability to return to their original shape, was poor and study proved to be limited accordingly. Prof. Lee’s research team combined nickel titanium alloy wire, which has little elasticity but significant restoring force, with shape memory high polymer, which has little restoring force but is very elastic. This combination enhanced the strain rate to 20%, and created a compound that repetitiously changes and restores without outside force.Heating and cooling buildings accounts for a large share of the energy used in non-industrial sectors. The technology developed by Ajou University’s research team is expected to contribute to lowering indoor cooling loads.“4D printing allows creation of a building that moves on its own using a variety of modules in a relatively easy and cost-effective way,” said Prof. Lee. “It can lower a building’s indoor cooling load and also be used in road shielding walls and solar panels.”This research was sponsored by the Research Leadership Program of the Korean Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF).<Model of the research team’s building façade experiment – the façade opens and closes in accordance with the surrounding temperature.>

-

529

- 작성자OIA

- 작성일2021-11-16

- 3940

- 동영상동영상

-

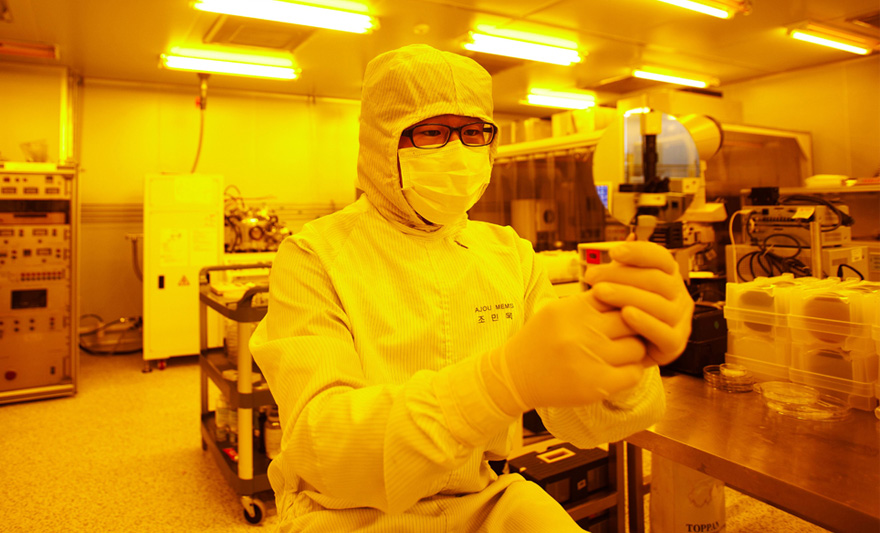

A research team led by Prof. Kim Jae-ho of Ajou University was selected to take part in the R&D to Promote Utilization of Public Research Results Project to assist the accelerated commercialization of source and basic technologies.The Korean Ministry of Science and ICT (MSIT) and the Commercialization Promotion Agency for R&D Outcomes selected an intermediary research group in each of the five technology fields and launched its R&D to Promote Utilization of Public Research Results Project. The selected intermediary research group will receive a total of KRW 8.4 billion from the government R&D budget over the next three years.The MSIT supports intermediary research that advances the technical readiness level (TRL) in line with corporate demand to quickly put into practical use the excellent source and basic technologies possessed by universities or research institutes. Through this support project, the goal is to upgrade the source technology owned by public institutions with technology maturity levels 1 - 2 to technology maturity levels 6 – 7 where prototypes are manufactured and certified.The Intermediary Research Group on Nanotechnology-based Bio/Electronic Components Materials from Ajou University will participate in this project. Prof. Kim Jae-ho (Department of Applied Chemistry and Biological Engineering, Graduate School Department of Molecular Science and Technology) will lead the Group, which aims to commercialize six bio/electronic component materials based on nanoparticle in-plane alignment and patterning technology. 대면적 입자 정렬 기술Particle in-plane alignment technology식품안전검사시장Food safety inspection market시장 선점을 위한 기업의 높은 관심High corporate interest in seizing market leadership2세부과제Specific Task 2마이크로 LED 시장Micro LED market식중독 검사시장Food poisoning inspection market1세부과제Specific Task 1수요기업Corporation with demand마이크로 LED 본딩 필름 시장Micro LED bonding film market탈모증 치료제 및 헤어케어 화장품 시장Hair loss treatment and haircare cosmetics market마이크로 LED 테스트 소켓 시장Micro LED test socket market3세부과제Specific Task 3마이크로 LED 칩 검사 시스템 시장Micro LED chip inspection system market탈모 연구용 및 후보물질 스크리닝 kit 시장Hair loss research and candidate substance screening kit market4세부과제Specific Task 4세포배양 시장Cell culture 약물 스크리닝 시장Drug screening market약물 스크리닝 시장 (효능/독성 평가)Drug screening market (efficacy/toxicity evaluation)연구용 줄기세포 3D 세포배양 용기 시장3D Cell culture container market for research-purpose stem cellsAjou University’s Technology Licensing Office (TLO) will also participate in the project to support the four specific tasks and commercialization of the school’s Intermediary Research Group. Products to be commercialized included in the research group's four specific tasks are Micro LED bonding and inspection material (Kim Jae-ho, Ajou University Department of Molecular Science and Technology); Food harmful bacteria on onsite diagnostic equipment (Yoon Hyun-cheol, Ajou University Department of Molecular Science and Technology); Efficacy evaluation of hair loss relief and haircare products organoids (Seong Yeong-gwan, Kyungpook National University Medical School); and a Culture of induced pluripotent stem cells for drug screening (Jeong Yeong-seok, Pusan National University College of Pharmacy).In addition to taking part in the MSIT Project, the Intermediary Research Group agreed to transfer the technology that will be developed through this project to a pre-determined company that has demand for the technology. Accordingly, an advanced technology fee of KRW 3 billion and a current technology fee based on the sales of developed products are separately contracted, which is expected to contribute significantly to enhancement of the school's research and technology commercialization capabilities. Along with the school’s Intermediary Research Group on Nanotechnology-based Bio/Electronic Components Materials, the Intermediary Research Group on Microalgae Cell Factory (Korea Research Institute of Bioscience and Biotechnology), the Intermediary Research Group on Semiconductor Analog Batch Design Automation (Pohang University of Science and Technology), the Intermediary Research Group on Green Hydrogen Production (Korea Institute of Energy Research), and the Intermediary Research Group on Diagnosis-Treatment Technology Convergence Commercialization (Chonnam National University) will take part in the R&D to Promote Utilization of Public Research Results Project.

-

527

- 작성자OIA

- 작성일2021-09-06

- 5874

- 동영상동영상

-

Ajou University will establish an independent technology holding company commercialize promising technologies within the university.An inauguration ceremony for the Ajou University Technology Holding Company was held at Yeonam Hall in the afternoon of August 5, 2021. President of Ajou University Park Hyung-ju and Head of Industry-Academia Cooperation Kwon Yong-jin, Director of the Research Institute for Innovative Medicine at Ajou University Medical Center Kim Cheol-ho, and other university officials were present. It was also attended by Kim Sun-yong, Standing Director and Park Jae-ho, Executive Director of Administrative Affairs at the Daewoo Educational Foundation. The ceremony began with a report presented by Kwon Yong-jin, Head of Industry-Academia Cooperation, on progress related to foundation of the company, congratulatory remarks by President Park Hyung-ju, an address by Director Kim Cheol-ho, and unveiling of the signboard.The company completed establishment and business registration in July this year with approval of the Ministry of Education. As a university technology company based on the Education Ministry’s Industrial Education Enhancement and Industry-Academia-Research Cooperation Promotion Act, Ajou University became the 76th technology holding company among universities in Korea. The CEO of the university’s independent technology holding company is Kwon Yong-jin, Head of Industry-Academia Cooperation, while Park Jang-ho, Deputy Head of Industry-Academia Cooperation, and Director Kim Cheol-ho will serve as directors, and Shim Gyu-cheol, Executive Director of Planning, will serve as auditor.Through establishment of this company, the school will be more active in discovering excellent technology, supporting the establishment of technology-based subsidiaries, and investing in promising venture companies. The goal is to establish a virtuous cycle of income generated through technology commercialization, which is then reinvested in R&D. In particular, the school plans to support society and companies as it leads technological innovation through swift commercialization, rather than keeping outstanding R&D achievements within the university.“Rather than pursuing research that remains inside the walls of a laboratory, Ajou University is seeking to contribute to our community by undertaking research that is needed by businesses and society,” said President Park, adding, “We will build a framework around this technology holding company and work to achieve coexistence and win-win growth with N4U Tech Holding Inc., where we utilize our existing expertise in collaborating with other universities.“Leading hospitals overseas are earning significant revenue through technology commercialization, technology marketing, and technology start-ups,” pointed out Director Kim Cheol-ho, who added, “As of 2019, we have secured considerable competitiveness in this field, ranking first in the country in terms of the number of technology transfers and resulting revenue. We will develop an industry-university-research convergence R&D center to be established on the site in front our nursing hospital, which will add to our competitive edge.”University technology commercialization refers to commercialization of the outcomes of university research activities through technology transfer and technology-based startups. Technology developed at the university can be transferred to a company or institution, or the technology holding company can commercialize the technology directly or through a subsidiary. Through successful commercialization, universities can maximize the benefits of research findings, thereby contributing to enhancement of corporate and national competitiveness and job creation. It will also diversify the school’s revenue sources.Ajou University systematically supports the entire commercialization process for excellent patent-based technologies, from research planning to intellectual property creation, technology transfer and start-ups, through an organization dedicated to technology commercialization, professional human resources, a joint technology holding company and an independent technology holding company. As a result of these efforts, the school has seen a steep rise in performance of technology commercialization over the past five years, recording KRW 3.35 billion in technology transfer revenue in 2020, ranking 7th in the nation.

-

525

- 작성자OIA

- 작성일2021-09-06

- 4878

- 동영상동영상

-

An Ajou University research team has developed a silicon semiconductor-based high-sensitivity infrared photodetector. The technology will be applied to a variety of fields that require high-sensitivity and high-efficiency infrared sensors, such as autonomous vehicles, solar cells, and medical diagnostic devices.Prof. Seo Hyung-tak (Dept. of Materials Science Engineering, Graduate School Department of Energy Systems Research) of Ajou University announced his team’s success in developing a high-performance silicon-based infrared light sensing device using flexoelectricity that is formed when the semiconductor crystal structure is strained. The related study was published in the online edition of Small Methods (IF=14.188), an international journal in the nano field, under the title, “Controllable, Self-Powered, and High-Performance Short-Wavelength Infrared Photodetector Driven by Coupled Flexoelectricity and Strain Effect” on July 19, 2021. The thesis was featured on the issue’s front cover. Prof. Mohit Kumar (Graduate School Department of Energy Systems Research) and Prof. Park Ji-yong (Department of Physics, Graduate School Department of Energy Systems Research) took part in the research as first authors.Optical sensors based on the photoelectric effect that converts light into electrical signals (a method that detects photocurrent by the movement of electrons and holes formed by light) are essential part to the utilization of new and renewable energy, smartphones, the Internet of Things (IoT), and optical communication. Infrared light detection has the widest application and is used not only for thermal imaging in the medical field and night vision but also as a front sensor for autonomous vehicles and object movement detection. Although there are various operating principles in an optical sensor for detecting infrared light, the method using the photoelectric effect generated by direct absorption of infrared light shows the highest sensitivity. This method can also have high value-added applications. However, in order to manufacture such a photoelectric effect, the band gap of the light-absorbing semiconductor (minimum energy required for a semiconductor material to absorb light) must be lower than the infrared light energy. For this reason, gallium arsenide and other compound semiconductor devices have been the main choice so far. However, such compound semiconductor devices are very expensive, have low detection sensitivity in the infrared region, and are limited in performance.Ajou University's research team focused on silicon, which had not been used as an infrared sensing material before. Applying flexoelectricity to the silicon material (effectively changing the electrical properties due to local deformation of the material, which causes a bandgap change) resulted in a strain effect (elasticity change to the semiconductor crystal structure caused by external stress and other factors, resulting in a change in physical properties) suitable for the semiconductor crystal structure, and the research team discovered it could significantly reduce bandgap energy to the same as or lower than infrared light energy. The research team used this to identify the light detection principle that maximizes optical response in the infrared region and succeeded in developing an optical sensor structure.The research team used a gold probe tip to sequentially apply micropressures of a few micro-Newtons in size to a diameter range of 960 micrometers to induce a sharp decrease in bandgap energy. Through this, it was possible to obtain an excellent device with high sensitivity, detection rate, and response rate to the light of infrared wavelengths using only a silicon semiconductor. This performance is superior to the conventional commercially-available infrared detection device.In particular, the research team used an alternating photocurrent in the photosensor to drive the device, using the photoelectric effect to negate the need for external power supply through absorption of infrared incident light that quickly turns off and on repeatedly. The detection speed of the device developed by the research team is 100 microseconds (0.1 msec), enabling high-speed detection, and using an atomic force microscope, it was confirmed that the same flexoelectricity effect-based infrared detection can be implemented at a size of 30 nanometers.“There is an important academic and technical significance in that we achieved infrared detection with an ultra-high sensitivity that was previously impossible with general-purpose silicon (Si) material widely used for sensors and integrated circuits,” said Prof. Seo. He further explained, “If applied, it will be possible to integrate a high-speed, high-sensitivity infrared detection device into an existing silicon integrated circuit, which can result in a low-cost, high-performance IoT sensor.”This research was carried out with the support of the Mid-Career Researcher Program and Young Researcher Program hosted by the Korean Ministry of Science and ICT and the National Research Foundation (NRF). A patent application is in progress.* Image provided by WILEY-VCH

-

523

- 작성자OIA

- 작성일2021-09-06

- 5116

- 동영상동영상

-

A research team led by Profs. Kim Jong-hyun and Kwon Oh-pil has successfully developed a high-performance gas sensor using an organic semiconductor. This will boost the electrical and optical gas detection capability of organic semiconductors and is expected to be utilized as a next-generation, high-sensitivity sensor to detect toxic gases.Profs. Kim Jong-hyun and Kwon Oh-pil (Department of Applied Chemistry & Biological Engineering and Graduate School of Molecular Science and Technology) and a research team at the Ulsan National Institute of Science and Technology (UNIST) School of Energy and Chemical Engineering (ECHE) jointly announced development of the gas-detecting sensor.Related research was published in the online edition of Advanced Functional Materials (IF: 18.808) an international journal in materials, under the title, “Strategic Approach for Enhancing Sensitivity of Ammonia Gas Detection: Molecular Design Rule and Morphology Optimization for Stable Radical Anion Formation of Rylene Diimide Semiconductors” on July 27, 2021.Profs. Kim Jong-hyun (photo left) and Kwon Oh-pil (photo right) of Ajou University and Prof. Sang-kyu Kwak of UNIST took part in the research as corresponding authors, while Oh Byoung-min and Park Seong-ha, students at Ajou University Graduate School Department of Molecular Science & Technology, took part as first authors.Ammonia (NH3) gas, a volatile organic compound, is a highly toxic chemical. Inhalation of high concentrations for long periods of time can result in headache, nausea, coughing, difficulty breathing, and other reactions. A variety of studies have been carried out on the development of high precision detection technology due to the change in resistance of semiconductor materials. However, conventional inorganic semiconductors involve highly complicated manufacturing process, rendering elements of the sensors as very expensive. In contrast, organic semiconductor materials are limited in terms of detection function and detection selectivity.The research team focused on ammonia gas and the organic semiconductor material based on rylene, which can selectively formulate stable radical anion. It discovered that when rylene-structured organic semiconductor material is exposed to ammonia gas, the intramolecular transfer charge reaction formulates stable radical anion and results in amplified electric current value and changes in light absorption. The research team utilized this to develop a high-performance gas sensor that can detect amounts of ammonia gas as tiny as 200ppb (parts per billion), while at the same time amplifying electric current to 1700% from ammonia gas.The research team also verified the principle of efficient charge transfer reaction that occurs between ammonia gas molecules and rylene organic semiconductor molecules using quantum computation and also proposed the principles of sensor and material design. “The organic semiconductor material proposed in this study has a very simple combination process and even the tiniest amount of ammonia gas can create an amplified electric current signal through radical anion reaction,” said Prof. Kim. “This will allow us to overcome cost and detection limitations, which are issues in conventional gas sensors, and resolve the related problems.” He added, “The material we have developed will enable the development of high-sensitivity ammonia gas sensors that are also competitively priced.”This research project was sponsored by the National Research Foundation (NRF) Research Facility Establishment Program (Molecular Science & Technology Research Center (MSTRC)), Basic Research in Science and Engineering (Mid-Career Researcher Program), and the International Cooperation and Leading Research Center Program (Functional Crystallization Center). <Principle of stable radical anion formation using rylene organic semiconductors and performance of high-sensitivity ammonia gas sensor using this principle><July 27, 2021 online issue of Advanced Functional Materials >

-

521

- 작성자OIA

- 작성일2021-09-06

- 5004

- 동영상동영상

-

A research team led by Prof. Lee Je-chan (Department of Environmental and Safety Engineering at Ajou University) will take part in the Regional Balance New Deal Project under the Korean Ministry of the Interior and Safety (MOIS). This project selects promising projects planned by 243 local autonomous regions nationwide for sponsorship.MOIS will select a total of 15 projects for financial incentives, which will be chosen upon document screening, a nationwide vote, and presentations. The total grant amount is KRW 30 billion.Prof. Lee’s research team (photo) will take part in the “Kenaf-based Green Bioplastic Development and Industrialization Project” under the Jeollabuk-do provincial government. This project is associated with the Green New Deal (one of Korea’s New Deal Policies for a carbon-free society) and aims to construct a system that covers all periods in the production of bioplastics using non-edible crops. The project period is two years and six months and carries total projected operating expenses of KRW 4.2 billion.The cycle for bioplastic production using non-edible crops includes the procurement of self-sufficient materials, development of technology to produce bioplastic materials, verification of environmental impact, and industrialization. The project will be managed by Jeonbuk National University and joined by the Korea Institute of Ceramic Engineering and Technology, Jeonbuk Agricultural Research & Extension Services, Korea Institute of Science and Technology (KIST) Jeonbuk, Movic Advanced Material Technology, and Ilshin Chemical. Prof. Lee’s research team will be responsible for developing technology to produce bioplastic monomers using material preparation byproducts.“We expect to reach domestic self-sufficiency in bioplastics—an area previously dependent on imports—and develop related technology through this project,” said Prof. Lee. “It will vitalize domestic bioplastic industries, secure price competitiveness in green plastic, and contribute to building a green carbon-free society.”A total of 15 notable projects were selected for participation in the MIS Regional Balance New Deal Project, including Construction of a Green Fiber Platform Using Recycled PET Bottles (Daegu Metropolitan City), Construction of Smart Mobility Empirical Hub (Gyeonggi-do), Construction of Precision Medicine Big Data Service Platform (Gangwon-do), and Smart Medicine Platform Pilot Model Project (Chungcheongbuk-do).

-

519

- 작성자OIA

- 작성일2021-09-06

- 4851

- 동영상동영상

-

Ajou University has transferred color-changing technology to detect hydrogen leakage to a company in a related field. The technology will create significant momentum in the hydrogen economy and safety.This technology was developed by a research team led by Prof. Seo Hyung-tak, and through a technology transfer agreement, generated more than KRW 2.5 billion in income. This is the largest technology transfer project in the non-bio sector for Ajou University since the university’s establishment.The technology transfer agreement ceremony held in Yulgok Hall on July 27, 2021 was attended by Ajou University’s President Park Hyung-ju, CEO of Daehyun ST Co., Ltd. Eom Ju-heung, Prof. Seo (Dept. of Materials Science and Engineering, Graduate School Department of Energy Systems Research) of Ajou University, and other participants from both institutions.This color-changing technology is a high-performance, high-precision sensor that can measure hydrogen concentrations with great precision, which is essential to safety in the use of hydrogen. Highlighted as a next-generation green fuel source, hydrogen is increasingly being applied to new industrial sectors. However, safety issues arising from its properties have always been a stumbling block. Since hydrogen has no color, is odorless and light weight, the risk of undetected leakage is high, and can result in combustion.This sensor technology is comprised of a liquid combination method and semi-conductor deposition method allowing multi-angle sensor processes to be constructed and customized for different purposes and mass production in various application fields.Existing conventional hydrogen detection requires a power supply, which can lead to hydrogen combustion from static electricity, and can only be installed in limited places. This new sensor is gaining wide recognition as a distinct technology in hydrogen leak detection as it primarily uses a chemical color-changing method, which enables the intuitive identification of hydrogen leaks at the starting point (without power supply). It also involves a multi-detection method which uses electrical signals for remote monitoring.The research team has also acquired numerous patents in source material technology for the hydrogen sensor to enhance its reliability. One of the original technologies it developed is nano material protection layers to increase material reliability, which is an issue with today’s hydrogen sensors.Daehyun ST plans to utilize this technology to offer hydrogen sensors to hydrogen charging stations and hydrogen automobiles. Building from this base, Daehyun ST expects to increase sales revenues not only in the domestic market but also overseas, including in Germany, Japan, and the United States.The transferred technology is particularly significant because it is a base technology fundamental to the Act on the Promotion of Hydrogen Economy and Hydrogen Safety Management (“Hydrogen Safety Act”), which will come into effect in February 2022. The Hydrogen Safety Act legally institutionalizes a hydrogen safety device for systemic promotion and safety management of the hydrogen industry. With this, Ajou University has secured a foothold to position itself as a pioneering institution in cutting-edge technology.Ajou University recorded earnings of KRW 3.35 billion from last year’s technology transfers, ranking seventh among universities nationwide. Earnings from technology transfers have been rising for five years. This is an amount paid by a company seeking to utilize the R&D results by an Ajou University research team and to acquire the relevant intellectual property rights. It is a major source of revenue from industry-academia cooperation and an indicator of the university’s leading research capacity. Ajou University operates a technology commercialization process for all periodic cycles that enables the results of its research teams to be widely utilized by businesses and society. It is committed to the commercialization of technology. Prof. Seo’s research team built the foundation for successful commercialization of this technology, and was selected for the Project to Support Mid & Large-scale Growth of the Research Industry under the Commercializations Promotion Agency for R&D Outcomes, itself under the Ministry of Science and ICT.* Photo: From left, Eom Ju-heung, CEO of Daehyun ST Co., Ltd., Prof. Seo Hyung-tak and President Park Hyung-ju of Ajou University.

-

517

- 작성자OIA

- 작성일2021-09-06

- 4964

- 동영상동영상

-

A total of nine research teams from Ajou University have been selected for the Fundamental Research on the Humanities & Social Sciences of the Korean Ministry of Education and the National Research Foundation (NRF). Established to provide systematic support for academic activities in the humanities and social sciences, the program selects beneficiaries by research method and researcher growth level and awards research grants.From Ajou University, five research teams were selected in the “Individual Research Group – Mid-career Researcher Support Sector”: ▲ Prof. Kang Min-hyeong (eBiz) – “A Study of Factors Impacting the Survival of New Users in Crowd-sourcing Websites and their Evolutionary Path: Application of Machine Learning Technique” ▲ Prof. Kang Joo-young (eBiz) – “An Experimental Study on the Impact of Robotic Autonomy, Sentiment, and Personification on Resistance and Attitude of Consumers using Unmanned Services” ▲ Prof. Lee Han-soo (Politics & Diplomacy) – “A Macro-Study on Changes in Party Politics in Korean Voters” ▲ Prof. Kim Eun-ha (Psychology) – “A Study on the Feeling of Unfairness among Baby Boomers: An Identification of Causes and Results and Development of Group Counseling Program” ▲ Prof. Jang Ji-won (Financial Engineering) – “Anomaly – Underreaction and Overreaction in the Stock Market and New Factor Model.” The research period is from 12 to 24 months.Two teams were selected in the Young Researchers Sector. Prof. Lee Eun-sang (Law School) will conduct a study on regulatory law principles in medicinal safety and ways to improve the current legal system, while Prof. Park Min-jae (e-Biz) will conduct research on AI governance and socio-economic system dynamics.In the General Joint Research Sector, Prof. Lee Wang-hwi (Politics & Foreign Relations) was selected to participate in a joint study on the politics and economy of China-Japan relations in the aftermath of the US-China dispute on the theme of supply networks for automobiles and semi-conductors. This sector supports joint research by at least two researchers and aims to develop rational methods to resolve problems for states and societies.In the Professor Sector of the Humanities and Social Studies Academic Research that supports academic research, Research Prof. Lee Hyun-joo was chosen to undertake a study on power structure based on the network of marriages and relatives of royal families from the Silla Dynasty era to the Early Goryeo era. This sector was installed to institutionally support non-tenure researchers outside the university so they can continue research and education.The Ministry of Education and NRF sponsor programs to support research in the Humanities and Social Sciences (including Arts and Sports), notably Basic Research on the Humanities and Social Sciences, Promotion of Humanities, Social Sciences Research Support, Popularization of Humanities, and International Exchange.

-

515

- 작성자OIA

- 작성일2021-09-06

- 3302

- 동영상동영상

-

A joint research team from Ajou University has developed a catalyst response technology that can produce hydrogen and carbon using methane, the main component of city gas, or natural gas. This is a cutting-edge energy technology that can concurrently mass produce green, affordable hydrogen fuel and high purity, high value-added carbon.The joint research team, led by Prof. Seo Hyung-tak (Dept. of Materials Science and Engineering, Graduate School Department of Energy Systems Research) and Prof. Kim Yu-kwon (Chemistry, Graduate School Department of Energy Systems Research) announced the development of technology to produce hydrogen gas and solid carbon directly converted from methane using a bubble column reactor injected with molten liquid alloy catalysts and zirconia. Their achievement was published in the online edition of Chemical Engineering Journal (IF=13.273) on July 7, 2021 under the title, “Enhanced Efficiency in CO2-free Hydrogen Production from Methane in a Molten Liquid Alloy Bubble Column Reactor with Zirconia Beads.” Lee Young-jae, a doctoral student at Ajou University, and Dr. Noh Yong-gyu took part as first co-authors, and another doctoral student, Kim Jin-a, and Prof. Shankara Kalanur also joined.Hydrogen, a clean fuel that emits water after use, has recently gained recognition as a next-generation energy source and is increasingly applied to diverse industrial fields. Mass production of hydrogen as fuel is commonly achieved by reforming fossil fuels, but the process emits CO2 that is nine times greater than the weight of hydrogen thereby produced.Due to this and other reasons, research has recently been active in photoelectrochemical water splitting technology using electricity or solar energy towards reducing emission of CO2, a major greenhouse gas. However, barriers have existed to these efforts as the unit cost of production has been at least five to six times the cost of reforming fossil fuels, and it could not be mass produced. Therefore, development of a way to mass produce hydrogen in an affordable and CO2-free manner is urgently needed if we are to realize a hydrogen economy, with hydrogen energy as a completely clean fuel.The Ajou University research team focused on methane gas (CH4), a major component in city and natural gas. When methane gas undergoes a pyrolysis process using solid catalysts at temperatures greater than 1000℃, it produces hydrogen gas and solid carbon. The solid carbon thereby produced could not be commercialized previously as it becomes deactivated. When solid carbon accumulates on the surface of the catalyst, it ultimately prevents the chemical reaction of methane gas there, as a result of which its reaction activity rapidly disappears.To address this limitation, researchers have recently turned their attention to the use of low-melting liquid metal (LM) alloy catalysts (liquid metal catalyst combining low-melting metals, such as tin, and high-melting metals, such as nickel, which are high catalyst activation). In other words, direct molten catalyst methane conversion technology injects methane gas into molten liquid metal alloy to produce hydrogen. At the same time, flotation and reaction are maintained due to the difference in carbon layer density on the surface of the liquid catalyst while also producing solid carbon.The joint research team developed a new method, based on this direct molten catalyst methane conversion technology, to discover that maximizing the surface area of the boundary between methane gas and liquid catalyst by reducing the residence time of methane gas inside the liquid catalyst and size of the methane gas bubble in the methane decomposition reaction using liquid catalysts is a critical factor in enhancing reaction efficiency. The research team developed a new reactor structure by additionally injecting zirconia (a mixture of zirconium and oxygen (ZrO2) which has a high melting point, is not easily decomposed, and is in a white crystalline form at room temperature) to the liquid catalyst in the reactor to minimize the size of the methane bubble and complicate the gas flow channel, which increased gas residence time.The adoption of a new reactor structure resulted in a high hydrogen conversion rate (about 37% methane at 985℃, lower than the existing temperature of at least 1000℃), and strong reaction durability as catalyst activity increased even after a long production period of more than 150 hours. In general, methane thermal decomposition reaction at 1000℃ or lower lowers the cost of thermal energy in accordance with reactor quality, but it also resulted in a rapid decrease in conversion rate. The Ajou research team overcame this stumbling block to record the highest conversion rate and continuous reaction at low temperature. The carbon produced using this new method was in a form that is high purity and high value-added (carbon nanotube and fiber filament). Such carbon can be used in batteries and fuel cells. This new development taps into the potential not only for environmentally-friendly mass production of hydrogen but also high-applicability carbon materials.“The existing hydrogen production methods using fossil fuels will inevitably undergo a rise in price due to trends toward stronger regulations on CO2 emissions,” said Prof. Seo. “This research is significant in that it has opened up a new green and affordable path of mass production of hydrogen.”He also added, “It can be remarkably economical if the carbon produced simultaneously and continuously with hydrogen is of high purity and has high value-added properties. We will continue our research and aim for its commercialization.” The research was sponsored by the Industrial Technology Alchemist Project managed by the Korean Ministry of Trade, Industry, and Energy (MOTIE), Korea Evaluation Institute of Industrial Technology (KEIT) and C1 Gas Refinery R&D Center managed by the Korean Ministry of Science and ICT and the National Research Foundation of Korea (NRF).This is a concept diagram of the production of hydrogen and carbon using direct methane decomposition based on molten liquid alloy catalysts: when methane is injected into the reactor, which is mixed with liquid metal alloy catalyst and zirconia, and heated, high purity hydrogen forms inside the liquid catalyst, while at the same time creating carbon fiber. Carbon fiber is of low density and will float to the surface. This is why it is not affected by the catalytic reaction and long hours of continuous production of hydrogen and carbon are possible.*PhotoFrom far left: Prof. Seo Hyung-tak, PhD students Lee Young-jae and Park Jin-a, and Prof. Kim Yu-kwon

-

513

- 작성자OIA

- 작성일2021-09-06

- 3363

- 동영상동영상

-

An Ajou University research team under Professor Kim Jong-hyun has been selected by the Ministry of Science and ICT (MSIT) to participate in the Korea-Australia Strategic International Joint Research Project. Professor Kim Jong-hyun (Department of Applied Chemistry and Biological Engineering/ Graduate School of Molecular Science and Technology) announced that his team will participate in the Korea-Australia Strategic International Joint Research Project together with Professor Jan Seidel’s team from the University of New South Wales’ (UNSW) Department of Materials Science and Engineering with the aim of developing an IoT-integrated independent sensor module for AI-powered diagnosis of livestock disease. The project period is two years (2021-2023) and will have an expected KRW 1 billion in project expenses.The MSIT has been leading the Strategic International Joint Research Project with an aim to address technological gaps and secure advanced technology through strategic international cooperation, with a view towards the impact of the Fourth Industrial Revolution and the technological abilities of research counterparts with the common goals of addressing climate change, micro dust, infectious disease, and other global challenges. The joint research team plans to develop an independently-run IoT sensor module that monitors the health of livestock in real time to diagnose and forecast pathogenesis, and create data mining analysis-friendly solutions for livestock diseases.A sensor module, which is the development goal of this project, will be designed around an independent power system which does not require replacing batteries and enables detection of various conditions of livestock health at the same time. Accordingly, it is expected to significantly reduce livestock management costs for Australian cattle ranchers as the country has a very large number of grazing livestock. The two countries’ research teams plan to lead studies focusing on their specialized fields. Professor Kim Jong-hyun’s team will develop an IoT-integrated independently-operated sensor module, while the Australian team will optimize a sensor module for localization and analysis of livestock health data. Narromine, a town in Australia, will provide the town’s livestock data as a test bed for the project so that the sensor module, the outcome of the project, can be adopted by the local agro-livestock industry. Professor Kim, who is heading the project, stated “Our team has secured advanced technology through continuous research collaboration with the Australian team,” and added, “Based on such collaboration, the bilateral project will enable us to successfully develop an IoT sensor module for diagnosis of livestock disease.” In addition, Kim said, “Australia is home to the world’s largest livestock headcount in a variety of species combinations, and is therefore very interested in the project. […] Our team has completed the first verification test of a neckband-type sensor module that we developed early on, and is currently discussing management authority of the final product with an Australian company.”Aside from joint technological development, which is the primary goal of the joint research project, Kim’s team plans to strengthen international cooperation and professional training by promoting active exchange of students and researchers between Ajou University and UNSW.In addition to Ajou University and UNSW, other involved institutions include the Korea Institute of Materials Science, the Korea Electronics Technology Institute, Pusan National University, Charles Stuart University of Australia, and the town of Narromine.인공지능 기반 가축질병 진단 IoT 통합형 독립구동 센서모듈 개발Developing an IoT-Integrated Independently-Operated Sensor Module for AI-Powered Diagnosis of Livestock Disease기존기술Existing Technology교체형 배터리 기반의 센서Sensors based on battery swap system사람에 의한 가축질병 진단Diagnosis of livestock disease done by humans자율전원 및 진단Autonomous power system and diagnosis제안기술(차별성)Proposed Technology (Differentiation)배터리 자율전원 IoT 디바이스 센서 모듈Autonomous battery-powered IoT device sensor module실내외 현장 적용가능Application possible inside or out자율전원 모듈Autonomous power module가축진단 데이터 구축Construction of livestock diagnosis data멀티 빅데이터 구축 가능Possible to construct multi-sourcebig data 전용, 진단Dedicated, diagnostic

-

511

- 작성자OIA

- 작성일2021-08-03

- 6741

- 동영상동영상

-

아주대 최근 기술이전 수익Ajou University’s Latest Technology Trasfer Revenue전국 7위7th in Korea11.8억원/19.6억원/21.4억원/26.3억원/33.5억원KRW 1.18 billion/KRW 1.96 billion/KRW 2.14 billion/KRW 2.63 billion/KRW 3.35 billionAjou University has led 5 consecutive years of growth in technology transfer revenues through continuous posting of outstanding performance in technology commercialization. Technology transfer revenue refer to money paid by companies to the university in exchange for intellectual property with an aim to use the research findings of university research teams, which signifies the university’s strength in research.In June of every year, the Ministry of Education publicly announces each university’s technology transfer revenues and contract performance through its annual University Information Disclosure, wherein Ajou University recorded a total of KRW 3.35 billion in 2020 university technology transfer revenues, ranking Ajou 7th in Korea. The average technology transfer revenueearned by domestic universities in 2020 is around KRW 710 million. Ajou is the only university with continuously growing profits from technology licensing in the latest five-year period. It recorded KRW 1.18 billion in 2016, followed by KRW1.96 billion in 2017, KRW 2.14 billion in 2018, KRW 2.63 billion in 2019, and KRW 3.35 billion in 2020.The scale and scope of technology transfers at each university represent the publication of papers by and academic performance of faculty members, which shows that a university’s research is actually benefiting society and companies, and indicates that material industry-academia cooperation is taking place. Various departments, including the departments of Engineering, Natural Sciences, School of Medicine, Colleges of Pharmacy, and Nursing, are all located on one campus which facilitates inter-disciplinary cooperation. As the university established a dedicated Technology Licensing Office and employs field-specific professionals, it has been able to operate a systematic and advanced support platform for technology commercialization through its Support Program Tailored to Intellectual Property Life Cycle. Towards providing more customized assistance, Ajou’s Technology Commercialization Team has established a full cycle support system for appointed professors—early, mid-term and later period. The Team also runs an outreach program on campus to raise awareness of technology commercialization. With an aim to promote more active utilization of its research outcomes, Ajou University is also actively involved in a variety of external programs including ▲the BRIDGE+ Program (under the Ministry of Education and the National Research Foundation), ▲the Intellectual Property Reinvestment Support Program (under the Korean Intellectual Property Office and Korea Patent Strategy Development Institute), and ▲the Technology Management Center (TMC) Program of Universities (under the Ministry of Science and ICT and the Commercialization Promotion Agency for R&D Outcomes). This year, a total of 413 tertiary institutions were included in the Ministry of Education’s University Information Disclosure (223 universities, 145 junior colleges, 45 graduate universities). Records were disclosed in 14 areas, 67 items, and 107 sub-category items, including school, students, finances, etc. In the technology transfer revenue category, KAIST ranked 1st followed by ▲Seoul National University ▲Kyunghee University ▲Yonsei University and ▲Korea University.

-

509

- 작성자OIA

- 작성일2021-08-03

- 6262

- 동영상동영상

-

-

507

- 작성자OIA

- 작성일2021-08-03

- 6308

- 동영상동영상